Towards a seamless data cycle for space components

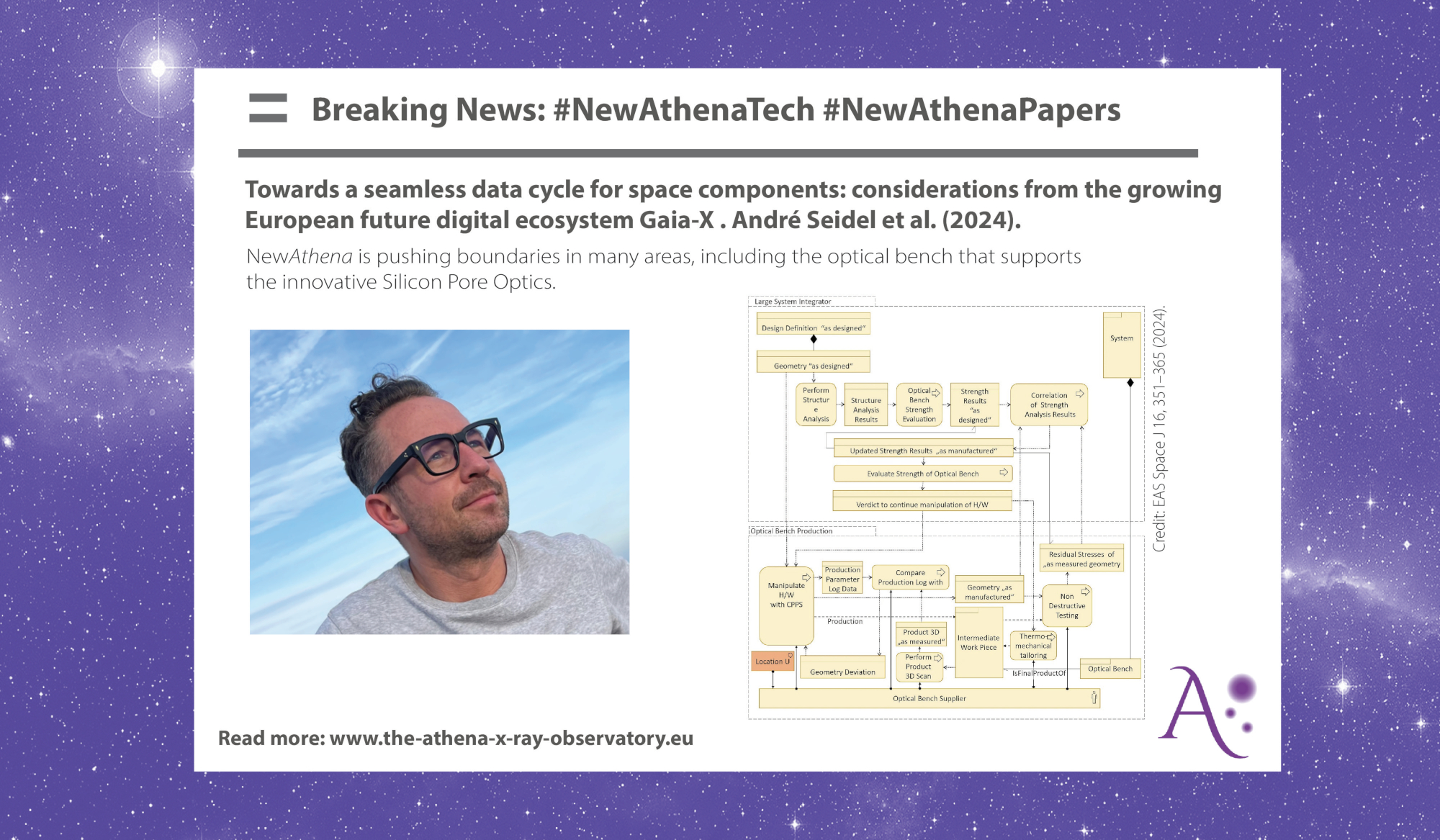

Caption (inset figure): The NewAthena Optical Bench Business Object Flow Diagram shows the sequential tasks and interaction of business objects through various process steps, highlighting dependencies, decision points, and feedback loops within the adaptive engineering and manufacturing workflow.

By A. Seidel

The traditional approach to realizing space hardware typically follows a serial process: Concept, Engineering, Manufacturing, Assembly, Integration, and Testing, adhering to the waterfall model. However, NewAthena is pushing boundaries in many areas, including the optical bench that supports the innovative Silicon Pore Optics. Finding a supplier capable of providing a blank with a diameter of nearly 3 meters and a height of 300 mm for the optical bench, while ensuring that the material would meet the intended properties, proved impossible. The large dimensions introduce significant risks of degraded material properties and residual stresses due to non-uniform cooling of the raw material, potentially compromising the suitability and precision of the final Optical Bench.

On the other hand, material properties can be tailored through customized heat treatments in the near-net shape, provided the actual properties can be identified and quantified according to defined requirements. Consequently, an adaptive approach was developed (see inset Figure). This approach integrates the initial geometric and mechanical design of the optical bench, “as designed” by the large system integrator (LSI), with a digital manufacturing method. It employs a Cyber-Physical Production System (CPPS) to identify the actual “as-manufactured” properties on the manufacturer’s side.

In simpler terms, the target geometry is achieved step by step, utilizing subtractive machining as a form of destructive testing based on machining data. This data, when analyzed using qualified models, helps determine the actual mechanical properties resolved in the workpiece coordinate system. The innovation here is that component characterization is integrated into the machining process itself, which can be described as a “designing hardware while manufacturing hardware” approach. By leveraging the machine data generated in the process, this approach reduces the effort and cost associated with separate characterization tasks. It also enables machine data-based reporting and verification cycles early on, minimizing the need for manual work by experts.

This approach allows for the updating of “as-designed” geometry and strength results with the corresponding “as-manufactured” values, ultimately delivering the final “as-built” model to the (digital) spacecraft system (see inset figure). In a broader context, the article explores how this type of digital collaboration can be realized within a shared data environment and how this approach can streamline tasks, reduce manual efforts, lower costs, decrease lead time, and increase safety in future space missions.